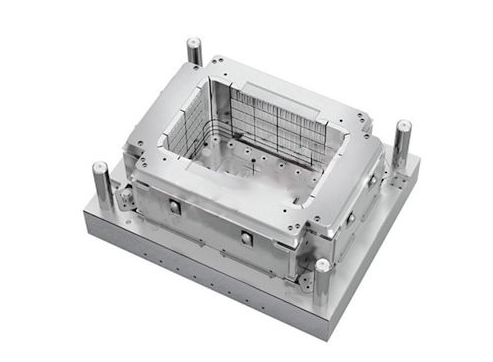

Polymer Mold Design

It is well know that plastic foldable crates/plastic pallet mould design is important point in high-speed crate injection molding solution. And optimal mould design will be improve production capacity so that maximize the value of sales.

The plastic foldable crates manufacturing process is as follows:

1. Foldable crate design drawing and measurement

2. 2D and 3D plastic crates moulding drawing software: UG, PRO-E, SOLIDWORK, AUTOCAD.

3. Machining by CNC , deep hole drilling, EDM, WDEM, precision carving and etc.

4. Foldable crates assembling

5. Testing: according to customer requirements.

Optimal foldable crates mould design advantages:

Reduce crates molding cycle

As HDPE flow index is 4-5, its flowing speed will be quicker. Meanwhile, it will also greatly reduce crate molding injection time so that to increase foldable crate production capacity.

Increase crate mold life

By using DIN 1.2344 (Thyssen, Germany, HRC 42-55, after nitriding is HRC 60 ), DIN 1.2311 (Thyssen, Germany, HRC 33-36, after nitriding is HRC 60 ) and 718 steel, crate mold life will be longer.

Optimized cooling

By adopting big diameter water lines and multi-groups design, crate molding cooling will be faster and better.

Simple plastic crate mould design

Our foldable crates mould design philosophy is simple structure so that mold maintenance will be easy in the future.

Efficient

Via mold flow analysis and previous molding experience, we aimed to achieve shortest cycle time so that to keep our folding crates productions competitive.

100% after-sales service

We offer more than a mold, but an optimal plastic collapsible crates solution.