With the rapid development of the manufacturing industry, plastic ODM (Original Design Manufacturing) factories have become the preferred partners for numerous brand owners and enterprises, thanks to their professional technical capabilities, efficient production processes, and customized services. Compared to the traditional OEM model, ODM factories can not only produce on demand but also provide a full-process solution from design to finished product. The following are the core advantages of plastic ODM factories, which help enterprises gain an advantage in the highly competitive market.

- Strong design and R&D capabilities

Plastic ODM factories are typically equipped with professional R&D teams, capable of providing customized design solutions based on customer needs. Whether it’s structural optimization, material selection, or functional innovation, ODM factories can leverage their extensive experience and technological accumulation to help customers achieve product differentiation. For example, in the fields of consumer electronics, medical devices, and automotive components, ODM factories can ensure product performance stability and compliance with industry standards through simulation analysis, mold optimization, and other means. - Flexible production to meet diverse demands

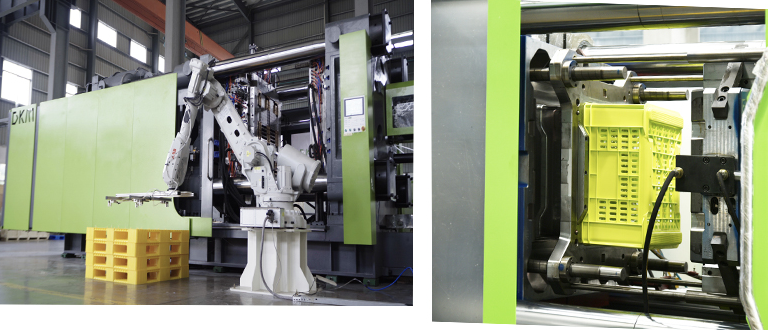

ODM factories typically possess advanced production equipment and mature process flows, enabling them to quickly respond to customers’ small or large-scale order requirements. Whether it’s injection molding, blow molding, extrusion, or rotational molding processes, the factories can select the optimal production method based on product characteristics, ensuring both quality and efficiency. Furthermore, ODM factories can also offer a variety of surface treatment options, such as painting, electroplating, UV coating, etc., enhancing the appearance quality and durability of the products. - Remarkable cost control advantage

As ODM factories integrate design, production, and supply chain resources, they can effectively reduce overall costs. On the one hand, factories can reduce material waste by optimizing mold design and production processes; on the other hand, purchasing raw materials on a large scale can also result in more competitive prices. For brand owners, choosing the ODM model not only saves R&D investment but also shortens the product launch cycle, enabling them to quickly capture the market. - Strict quality management system

High-quality plastic ODM factories typically obtain international certifications such as ISO 9001 and IATF 16949, ensuring that every step from raw material storage to finished product delivery meets high standards. Through automated testing equipment (such as coordinate measuring machines, spectral analyzers, etc.) and strict quality control processes, the factory can effectively avoid the production of defective products and ensure product consistency and reliability. - Strong supply chain integration capability

ODM factories typically establish long-term partnerships with upstream raw material suppliers and downstream logistics service providers to ensure a stable and efficient supply chain. Whether it’s the procurement of specialized engineering plastics or the coordination of cross-border logistics, the factory can provide a one-stop solution, reducing the burden on customers in supply chain management. - Improved intellectual property protection

For brand owners, the confidentiality of product design is of utmost importance. Formal ODM factories will sign strict non-disclosure agreements (NDAs) with their clients and adopt measures such as data encryption and access control to ensure that design schemes and core technologies are not leaked. - Global service capability

Many large ODM factories have set up branches or cooperative production bases overseas, enabling them to provide localized support to customers worldwide. Whether it’s the environmental compliance requirements in European and American markets, or the cost optimization needs in emerging markets, ODM factories can respond flexibly and help customers smoothly enter the target market.

Conclusion:

Plastic ODM factories have become indispensable partners in modern manufacturing, leveraging their comprehensive advantages in design, production, cost, quality, and other aspects. For brand owners, choosing an ODM factory with strong technical capabilities and comprehensive services can not only enhance product competitiveness but also facilitate efficient resource integration and drive sustained business growth. In the future, with the widespread adoption of smart manufacturing, ODM factories will further upgrade towards digitalization and automation, creating greater value for customers.