Foldable crates are widely used in the big supermarket chains, 24-hour convenience store, shopping mall, department store, light industry, clothing, home appliances, fruit &vegetable, food processing closed loop distribution system and so on.The foldable crate of MoldingMed has been developed continuously by our R&D department for a long time. To ensure market requirement, we take a high attention on foldable crate design. Besides, by adopting international fashion foldable crate design, our foldable crates divided into folded in half and pour inside type two kinds folding methods. That’s why the MoldingMed foldable crate is famous for its unique structure.

Raw material of foldable crate

MoldingMed foldable crate is molded with special HDPE or PP material to achieve highly durability. The melting speed of special material is 3.6-4.5 g/10 minutes, the tension is over 25 Pa, the tensile strength is over 60% and the contraction force is over 40 Pa.

Normally HDPE material has little branching, but the special new material used for MoldingMed foldable crates gives it stronger intermolecular forces and tensile strength than LDPE. Its surface is harder and more transparent, and it can withstand higher temperature (120 °C/ 248 °F for short periods, 110 °C /230 °F continuously), in order to reach the requirement of durability. It should be noted that HDPE, unlike polypropylene, cannot withstand the general high pressure.

Storage room saving of Molding foldable crate

Most of plastic crate, especially for large crates, it takes much space to store them and it’s inconvenient to carry and transport them. But foldable crates, because of its foldability, can reduce the space by 25% - 50% than ordinary boxes, which finally reduces transportation and storage costs by about 50% - 75%.

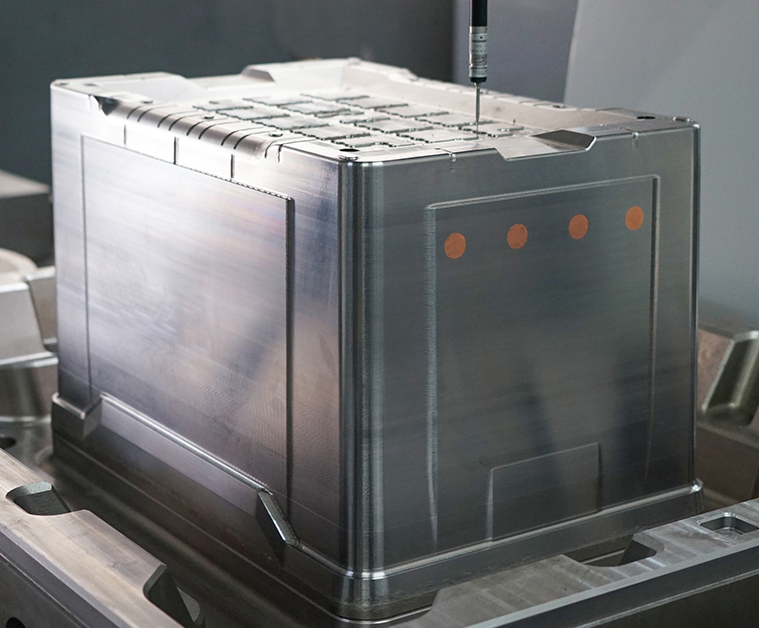

Rapid heat cycle molding technology for MoldingMed foldable crates

MoldingMed foldable crate is a kind of high-tech foldable crate, applies rapid heat cycle molding technology to ensure the quality and durability of foldable crates. As said above, MoldingMed uses special HDPE material with low melt flow index, under the usual injection molding technology, there would be defects such as flash, non-uniform wall thickness, insufficient weight, short filling and etc., which would affect the life of foldable crates. While the rapid heat cycle molding technology can solve these problems perfectly with a considerable competitive price.

By taking good foldable crate product design, our foldable crates had below advantages

1.The material of foldable crate is combined polypropylene with polyethylene, so its weight will be lighter and guaranteed life will be longer. And with poisonless and tasteless, It can even be used in foods which is very convenient to clean.

2. All foldable crate development and product design are based on logistics standard and specialism. Besides, we also consider to maximize the economic value of foldable crates user. Hence, our foldable crate of all size is through strict mathematical calculation, combining logistics instrument pallet with 1200*800and 1200*1000 ,20 feet container ,40 feet container , it can be stack precisely , even with different series crate stacking .It can be interchangeable for the shorter side which can help you to make up foldable crates with more size , the same applies to covered and uncovered foldable crates.

Many users maybe want to know:

Why MoldingMed uses the Rapid Heat Cycle Molding technology to make foldable crates? What is its advantage? What are the technical points of these foldable crates?

The answers are as follows:

Why MoldingMed uses the Rapid Heat Cycle Molding technology to make foldable crates?

Rapid Heat Cycle Molding (RHCM) is a new and advanced technology for plastic molding, MoldingMed apply this technology to make up the surface defects of foldable crates and improved the foldable crates’ surface quality and strength.

what's RHCM's advantages?

A. It is specialized in removing the welding wires and sliver marks on surface of foldable crates.

B. Good at improving the fluidity of plastics when the molding foldable crate.

C. It can enhance the foldable crates surface as a mirror.

TEL: +86 18957607029

ADD:369# XinJiang Rd., Xinqian Street,

Huangyan Taizhou, Zhejiang, P.R China

E-MAIL:sinosales3@moldingmed.com

ABOUT US

Youtube